Shenzhen JK Plastic Mold Co., Ltd.

Scale: The mold manufacturing area is 12,000 square meters, and the injection molding area is 5,000 square meters. There are independent office areas, production areas and living areas. It has 25 sets of CNC machines, 3 sets of wire-cut machines, 8 sets of EDM machines and other processing machine. 4 sets of CMM measurement machine, 1 set of Blue light 3D scannerand other measurement machine. 13 sets of injection molding machines from 90 tons to 1,000 tons, 1set of IMD foil feeding machine and 2 sets of ERP internal production, finance, procurement management systems and external customer order management systems.

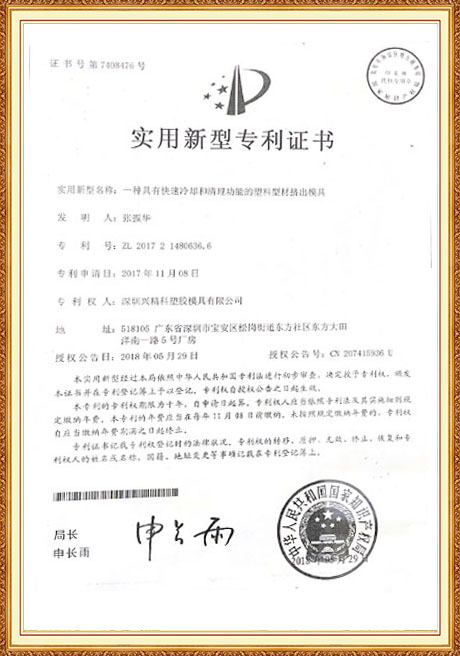

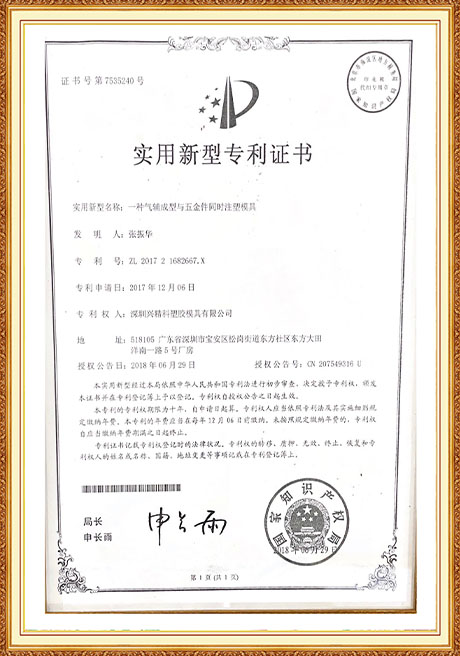

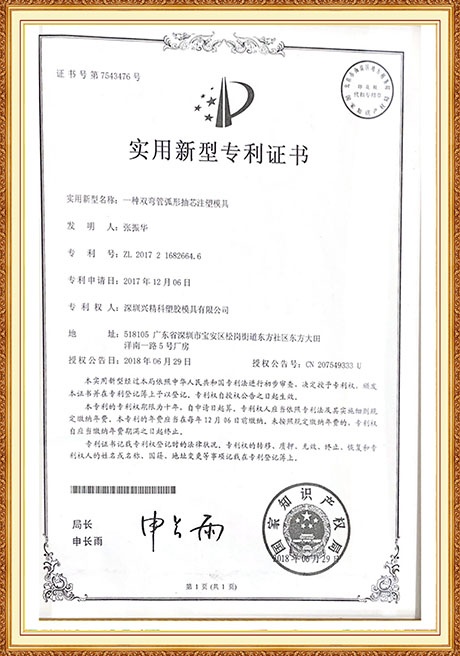

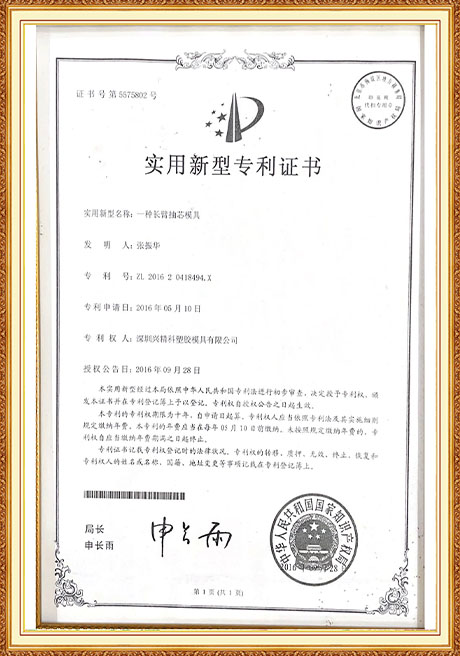

Quality control: Complete ISO management system, various international and domestic authoritative certifications: ISO9001, TS16949, etc.

Product and price advantages: It has its own mold manufacturing factory, mold base manufacturing factory and injection molding factory. 90% of the parts are self-produced, with better quality assurance and easier price control. The sales and service network covers the United States, Canada, Mexico, Switzerland, Spain, France, the Netherlands, the United Kingdom, Italy, India, Japan, Thailand and so on. JK adheres to the business philosophy of "keep improving, scientific management" and "doing business is being a person", and has won the respect and trust of customers and employees at home and abroad. Over the past 20 years, relying on a senior and stable management team and a large number of outstanding professional talents, JK has won the unanimous recognition of customers with high-tech design and manufacturing, excellent product quality and perfect after-sales service, and has maintained rapid and stable development.